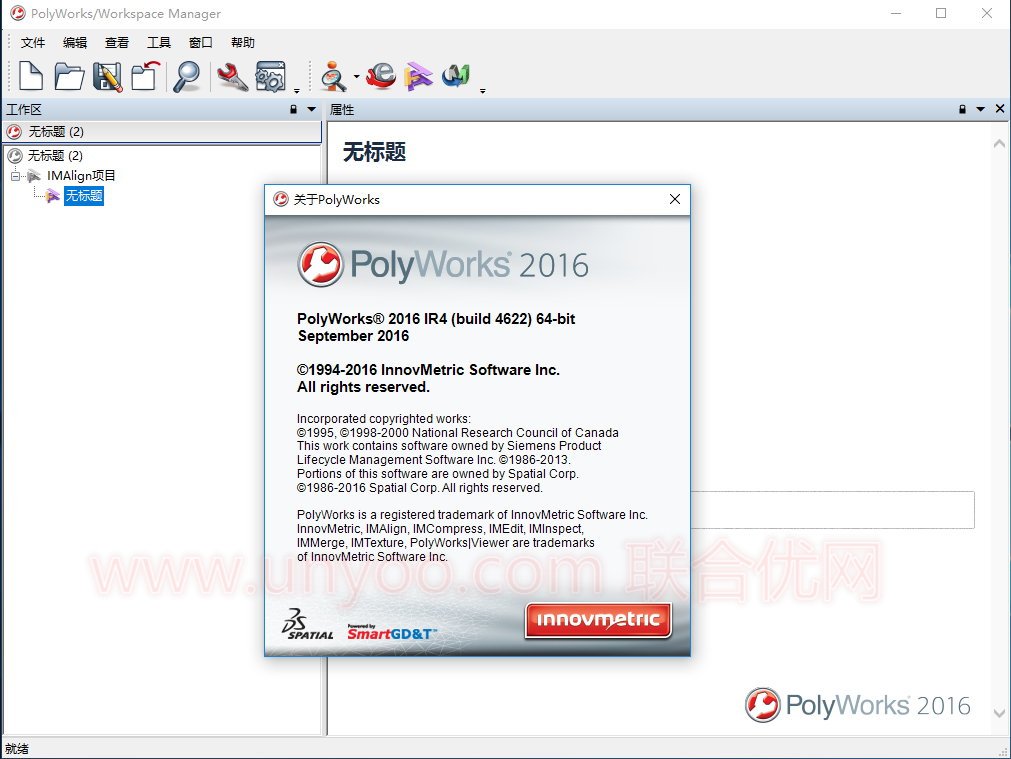

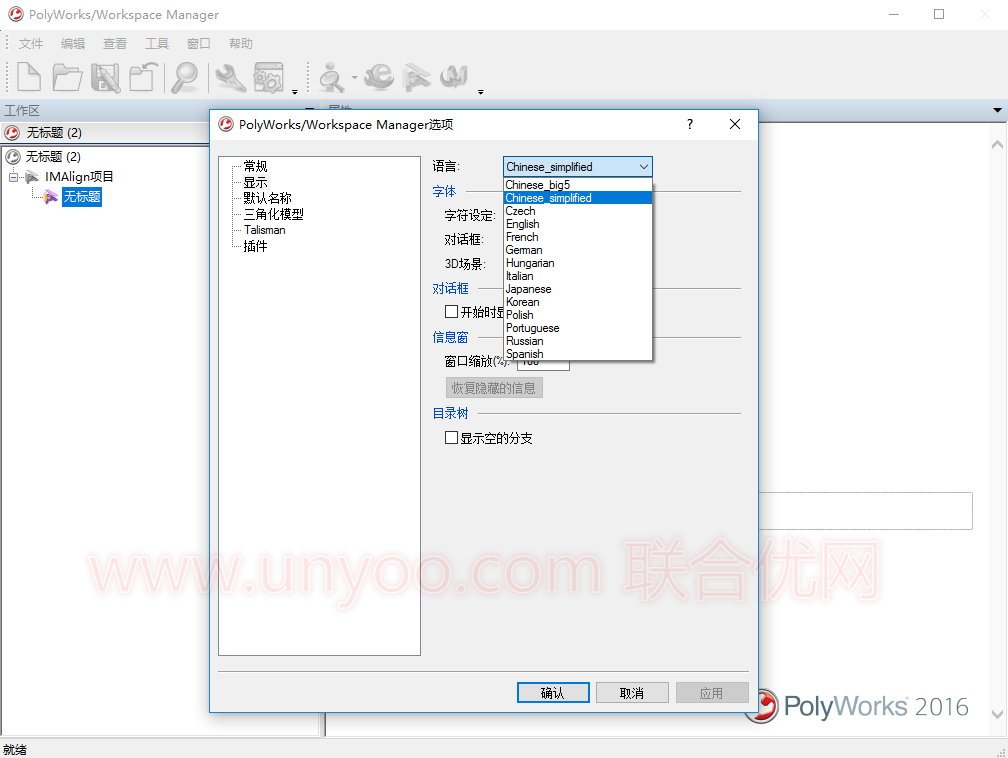

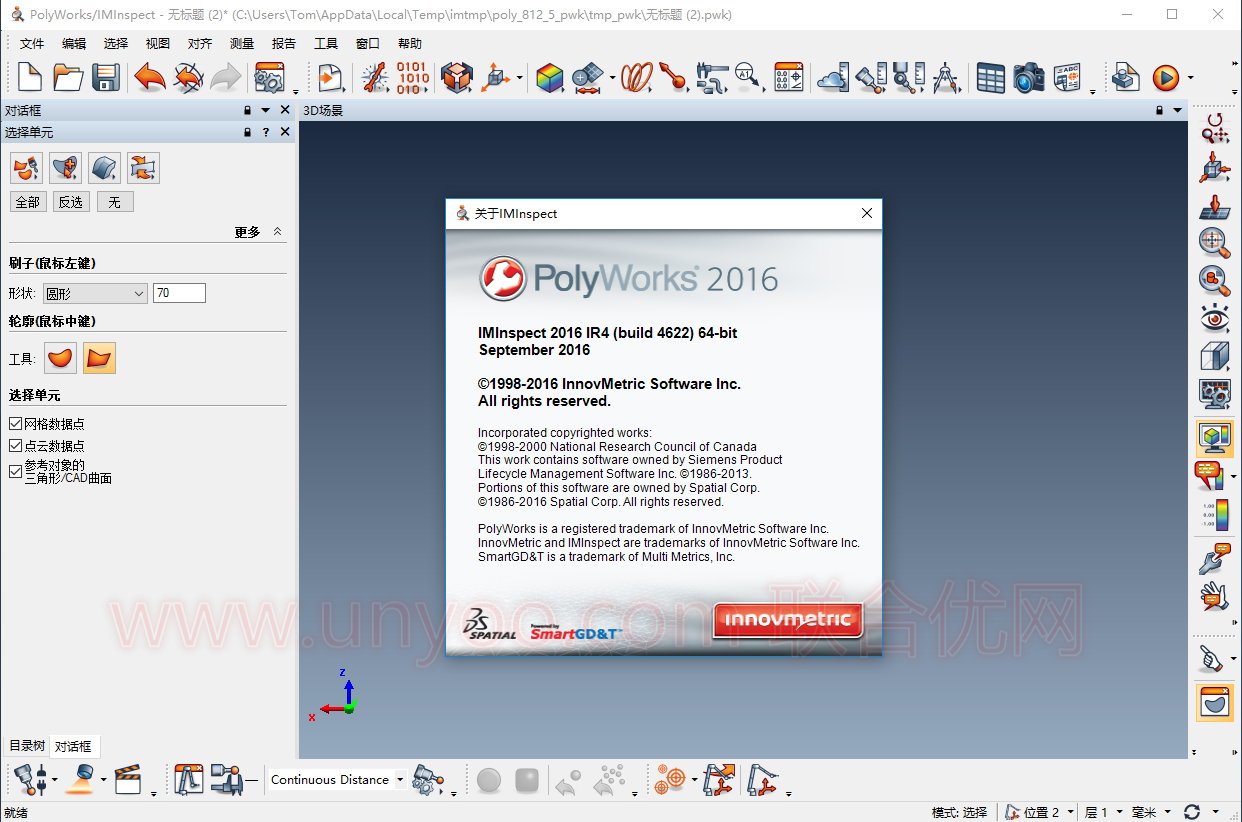

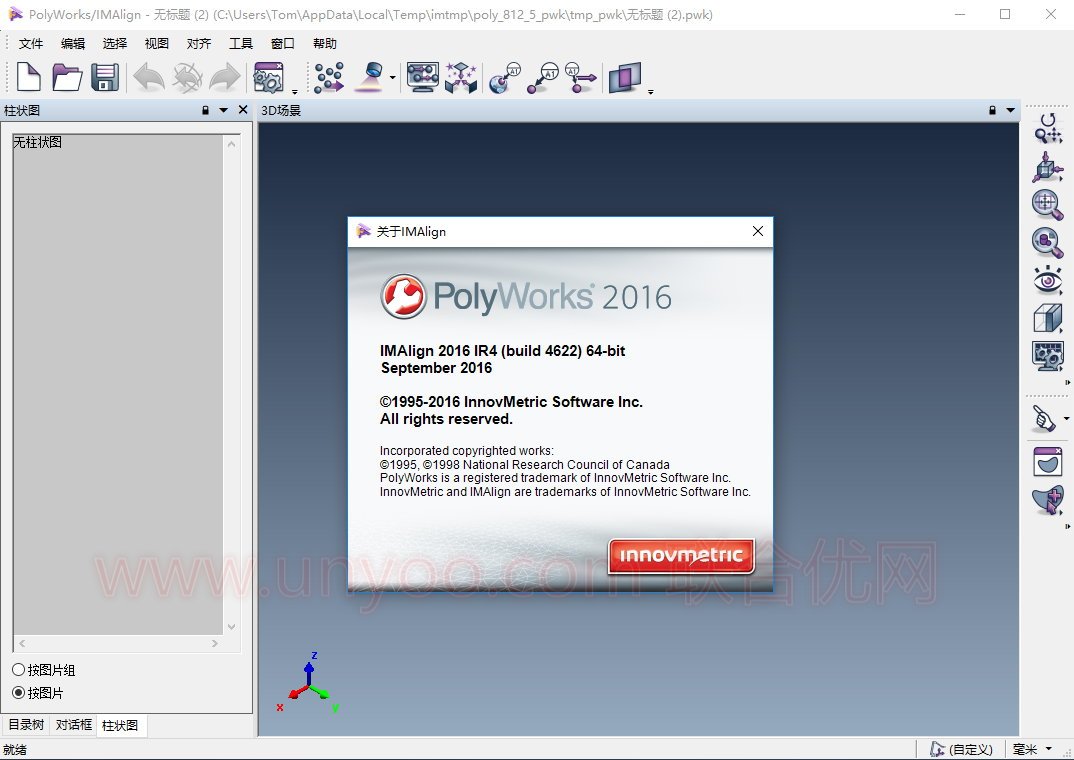

InnovMetric PolyWorks 2016 IR4 多语言中文注册版-3D测量软件-简体/繁体中文下载

InnovMetric软件公司,3D测量软件解决方案的领先供应商,已经发布了PolyWorks 2016 IR4,该公司的通用3D测量软件平台的最新版本的更新。 PolyWorks 2016 IR4完全支持探测和固定CNC三坐标测量机激光扫描,并分享一个真正的通用3D测量的工作流程,将允许用户一个共同的框架内运作的任何类型的便携式计量和数控三坐标测量设备,从单一的软件模块,并使用类似的工具和方法。

PolyWorks:标准点云工程解决方案 成立于1994年加拿大魁北克,InnovMetric软件在制造领域拥有世界上最大的高密度点云软件客户群。领先的汽车和航空OEM制造商,如宝马、波音、戴-克、福特、通用、本田、劳斯莱斯、丰田和大众及其供应商,在日常的点云扫描、尺寸分析、比较至CAD和逆向工程作业中使用PolyWorks。

一个共同的框架下运行的便携式计量和数控三坐标测量机设备现在可以在PolyWorks 2016推出两个新的主要组成部分:测量序列编辑器和离线仿真。

测量序列编辑器

PolyWorks 2016分享了功能强大的播放工具,检查自动生成一个一步一步的引导测量序列捕获使用便携式测量设备的新一片的3D数据集。PolyWorks 2016允许其自动生成序列的定制扩展播放检验技术的能力。使用新的序列编辑器,用户现在可以:

– 配置测量操作的顺序;

– 控制装置位置移动;

– 触发CMM特定的操作,例如将探头移动到特定位置或改变测量工具的方向;

– 轻松添加的指导信息和图像;

– 创建业务的条件块;

– 插入宏脚本,开辟无限的流程定制的可能性。

离线模拟

PolyWorks 2016还分享了一个新的易于使用的离线仿真功能,自动生成模拟的点云数据和从测量部的CAD模型探测点,将通过一个模拟的测量工作流一会儿。离线模拟允许用户快速创建模拟被测对象组件,数据比对,数据彩色图,几何控制表,3D场景的快照,而真正的测量任务前的检验报告,而无需访问测量设备。 PolyWorks 2016离线模拟也完全支持CNC三坐标测量机,使用户能够控制虚拟设备上的探测和激光扫描工具的方向和轨迹。

通用检查项目

由于PolyWorks 2016的普遍3D测量的体系结构,只有最小的改变将需要做出一个PolyWorks的检查项目,以便它可以与多个硬件平台上使用,以优化对象的测量方法和他们适应不同的测量原理。其结果是,PolyWorks 2016打开了普遍的检查项目和设备互操作性的新时代,以确保完全的灵活性,为客户选择合适的测量设备为他们的需求,并最大限度地发挥他们的3D测量投资回报。

PolyWorks的(PW) – 多功能软件制作公司InnovMetricSoftwareInc,用于激光扫描数据的处理:逆向工程,产品,建筑,监控,地面变形的问题,和许多其他几何形状的控制.. PolyWorks的软件可以让你迅速开展工作并有效地与非常大量的数据。 PolyWorks的由多个模块,并具有广泛的能够简化和加快与数据的工作的工具。值得注意的是,复杂的可以让你与所有品牌的三维扫描仪获得的数据的工作是很重要的。

InnovMetric Software Inc., the leading provider of universal 3D metrology software solutions, announced the launch of PolyWorks 2016, the latest release of the company’s universal 3D metrology software platform. PolyWorks 2016 fully supports probing and laser scanning on stationary CNC CMMs, and delivers a truly universal 3D metrology workflow that will allow users to operate any type of portable metrology and CNC CMM measurement device within a common framework, from a single software module, and using similar tools and methods.

With PolyWorks 2016, portable metrology and CNC CMM operators are now able to:

– Define a measurement plan without being physically connected to a specific measurement device;

– Specify geometry controls on measurement objects and prepare inspection reports;

– Connect to a non-contact or a contact-based portable metrology device, or to a CNC CMM controller (from Hexagon, Mitutoyo, Nikon, Pantec, Wenzel, and I++ servers), to play the measurement sequence;

– Review measured object geometry controls and reports, or multipiece inspection results through the built-in SPC functionality.

Operating portable metrology and CNC CMM devices within a common framework is now possible with the introduction of two new major components in PolyWorks 2016: the measurement sequence editor and the offline simulation.

Offline simulation

PolyWorks 2016 also delivers a new easy-to-use offline simulation functionality that automatically generates simulated point cloud data and probed points from a CAD model of the measured part, while going through a simulated measurement workflow. Offline simulation allows users to quickly create simulated measured object components, Data alignments, Data color maps, geometry control tables, 3D scene snapshots, and inspection reports before the real measurement task, without needing access to a measurement device. The PolyWorks 2016 offline simulation also fully supports CNC CMMs, allowing users to control the probing and laser scanning tool orientations and trajectories on a virtual device.

Universal inspection projects

Thanks to the universal 3D metrology architecture of PolyWorks 2016, only minimal changes will need to be made to a PolyWorks inspection project so that it can be used with multiple hardware platforms to optimize object measurement methodologies and adapt them to different measurement principles. As a result, PolyWorks 2016 opens a new era for universal inspection projects and device interoperability, ensuring total flexibility for customers to select the appropriate measurement devices for their needs and maximize the return on their 3D metrology investments.

下载仅供下载体验和测试学习,不得商用和正当使用。

![PICS3D 2020破解版[免加密]_Crosslight PICS3D 2020(含破解补丁)](/d/p156/2-220420222641552.jpg)